Sheathing to Interior vs. Exterior

Hi,

I will be framing our new house come spring 2022 after the original company not longer seems interested and other framing company are either fully booked or charging a fortune for labour.

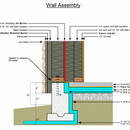

Our wall assembly has the sheathing (in red) on the inside of the 2×6 wall to avoid “cold sheathing”. This make building the wall a bit more laborious since the sheathing and taping can’t be done before the wall is lifted in place.

Is there any real risk is the sheathing is place on the exterior side of the 2×6 wall?

Thank you,

Arnold

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

That looks like a lot of insulation and a very expensive wall to build.

What is the R value? 56?

What lead you to believe that R value would be optimal?

I think if you did the math given today’s costs that amount of insulation will never recover its costs in energy savings. Seems like you would be better off spending more on solar panels and less on insulation and be at net zero for less money.

Walta

Hi Walta,

The wall R-value is around R-60 which is a bit less than what Passive House would require which we using as a guide when designing the house. I agree it's on the high side though the price of propane and hydro in my area (Ottawa, Canada) is constantly going up so I'm sure at some point the extra cost will pay itself off though likely many years down the road.

As I had mention in a previous post, the high R-value is because my wife wanted to keep the exterior rigid insulation and I had to just pick my battle. I did get half of the required rigid insulation at decent price from a local store that has had it for a while and kind of wanted to get rid of it.

That whole ship has sailed and now looking at the best approach to build this wall assembly without compromising on quality.

Thank you,

Arnold

删除d

Hi Malcolm,

I appreciate the feedback and I know we have discuss the rigid insulation (Rockwool Comfortboard) in other threads.

This question is to find out if the extra effort of putting the sheathing on the interior side of the exterior 2x6" wall is worth the additional work.

Thank you,

Arnold

Arnold,

Sorry - the mistake is mine and I have deleted my post. I had forgotten you were using rock-wool. The risk is minimal, and the many benefits of having the sheathing on the exterior outweigh it.

I am glad to hear that. I was leaning towards exterior sheathing which would make my life a lot easier during the framing stage and air sealing but I didn't want to make that change simple on that basis.

Arnold

Arnold,

Exterior sheathing on well air-sealed walls with a rain-screen is safe. Having the sheathing located there also helps a few other things.

- The sheathing can be continuous so it works better as a shear diaphragm and ties the whole structure together.

- It's easier to detail as an air-barrier.

- It provides a substrate for your WRB, and good backing for furring and flashing.

- It's much easier to work on the exterior when you have a solid surface to lean ladders on.

I agree with Walter that that looks like an overly complex wall assembly, but aside from that, I don't really see any problems with it. Exterior rigid foam doesn't really gain you as much on a double stud wall as it would on a "regular" single stud wall though, so understand that that rigid foam isn't doing much more than thicker batts would in this particular case.

The only thing I would be concerned with about the rigid foam, aside from the costs it adds to the project, would be that I would want a vapor open rigid foam here. The reason is because your sheathing is in the middle of the wall, and I'd wanted to have at least a little bit of drying potential for that outer layer of batts. You could use EPS or kraft/fiberglass faced polyiso here. I would avoid XPS or foil-faced polyiso. Hopefully whatever you've bought is one of the more vapor-open types of foam. Comforboard would work here too, and is the most vapor open option, but also the most expensive.

I don't see a callout for a sill seal gasket, just a bead of sealant on either side. I would put a gasket under the sill plate in addition to those beads of sealant. There was some discussion about this on a recent Q+A here, I think it was yesterday or maybe the day prior. Remember that the sill seal gasket isn't just an air seal, it also acts as a capillary break on top of the masonry wall which is important.

Bill

Hi Bill,

There is a sill gasket that will be installed and the exterior rigid insulation is Rockwool Comfortboard so the wall can dry in both direction.

I was trying to figure out if the extra effort of putting the sheathing on the interior side of the exterior 2x6" wall is worth the additional work while building the walls.

Thank you,

Arnold

Weren’t you going to use Rockwool for the exterior insulation? What type of rigid insulation makes a big difference.

Hi Kyle,

You are correct that we'll be using Rockwool Comfortboard for the exterior insulation.

Arnold

What are you planning to use for the interior vapor retarder?

We'll be using ProClima Intello Plus as the vapour barrier just behind the drywall.

Arnold

With Rockwool as the exterior rigid insulation and with intello on the interior, I see no reason to put the sheathing on the interior.

To my ear it sounds like you are committed to your plan but it seems you are having trouble finding someone to build it.

Seems to me you could cut the material and labor budgets by eliminating the exterior insulation eliminate the second sheeting layer spread the current double walls and fill the void with damp spray cellulose hitting you R60 goal for 20% less money and be more likely to find a builder.

The passive house equations are beautiful but there are no dollar signs in the equation. In terms of return on investment passive houses rarely make financial sense.

Consider building a BEopt model of your home use your local weather data your electric rates, your interest cost, your estimate of inflation and build the house that has the lowest cost of ownership.

https://www.nrel.gov/buildings/beopt.html

Walta

删除d

I am not a pro, so take my advice for what it is - a lesson learned from a DIY-heavy guy that learned the hard way. I am building a small house and I designed it to have the sheathing on the inside and rigid insulation on the outside, very similar to your design (but much thinner). I also built it myself, with no experience doing so.

Having the sheathing on the inside complicates EVERYTHING. There are accepted procedures for framing walls and very few of them are done the same if the sheathing is going on the inside. That meant that I felt like I was making it up as I built and, well, I had notable problems because of that. Were I to do this again (or build another house), there is no possible way I'd put the sheathing on the inside!

不过我非常新,。如果你find a contractor that is experienced with this style of building, then I'm sure it would pose no problem. I would guess that an inexperienced crew would run into similar issues that I did, though, and that might be why it's hard to find one that will accept the job.

Hi Kurt,

Your concern is why I started to wonder if it's worth installing the sheathing on the inside versus the exterior as it is traditionally done. Malcolm also brought up some of the issue I was concern with, the air barrier being the main one.

Arnold

I have to ask are you in a position to build this home without a construction loan? Getting a loan seemed all but impossible without a general contractor when I did mine.

Having the permit but no builder could be problem in most towns because getting the permit starts the clock most permits have a one year time limit. Yes it is possible to get 90 day extension but are often cranky about it and you can’t get another without showing progress. Yes they have been known to demolish incomplete buildings.

I wish you luck with your build.

Walt

Walter, I've been involved with plenty of projects that take several years to complete and permit expiry has never been a problem. Granted, I do mostly commerical work, so that might be part of it (commercial projects tend to be bigger and take longer compared to typical residential projects), but I've never seen the city object to permit extensions for what I would call "professional" projects.

A "professional" project is one that can be shown to be making normal amounts of progress barring anything outside of your reasonable control (weather delays, unexpected pandemics, etc.). Where I HAVE seen problems is large DIY projects that are poorly done, with lots of major code violations that show the builder doesn't know what they are doing. I've also seen problems on projects that lose their funding. We had one large mixed used development here that was going in around the time of the economic downturn back around 2008. They lost their second (might have been third) round of funding and pretty much abandoned the project (after spending over $100 million and completing one of the big parking structures!).

That project sat abandoned for a number of years, with multiple partially built structures deteriorating in the weather. THAT is something the cities want to avoid, and rightfully so! This particular project was eventually sold to another developer, who demolised all but the one completed parking structure. They now have a small hospital and a bunch of retail stores in there, and it's a working property now.

The cities are concerned with the buildings being safe, and not having blight like partially completed projects with no hope of the builder ever finishing. You're unlikely to have problems with the cities if they can see you're running things professionally and you're on track to complete your project at some predictable point in the future.

Bill

Hi Walter,

We will not be using a construction loan because it is not flexible enough for how we plan to build and that was still the case before the framing company lost interest in our project for whatever reason.

我们已经有了我们的资金来自储蓄s and the equity we on our house from making yearly additional payments for the last 12 years.

I am not very concern about the permit and the City. I know of a number of owner/builder how have taken longer than one year to complete their house build. Like Bill said, they were all working to make progress the build and not letting it sit idle for weeks or months.

Arnold