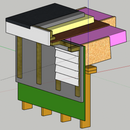

Unvented low slope roof detail, Zone 6

Hello all, A quick intro:

First time poster here. I’ve been a lurker on FHB and this site for some time now and have always had a passive interest in construction/building science outside of my “real” job. Currently I have the opportunity/time to tackle a few larger scale projects on our circa 1900 New Englander style home located in Southern Maine (zone 6). I want to do things “the right way” and also maintain the charm and character of this old house within reason.

Current project: Deconstruct 12’x16’ single story section under flat roof extending from north gable end of main 24’x28’ 1-1/2 story house and reconstruct an addition in same location. Deconstruction is complete. I saved as much material as possible and will re-use elsewhere.

A few key details for the planned addition:

Single story, approx. 15’ x 16’ Low slope shed roof, ~1/12, unvented (low slope due to need for peak to fall under 2nd floor window elevation).

.060 EPDM single sheet

ICF foundation, pinned to shallow bedrock (6-30” deep), tied to existing main house brick/stone foundation.

There is no room for an accessible crawlspace, I plan to have a slab with radiant heat.

I’m in the process of working through the key construction details in all of the critical areas with the aid of this site, codes, and various other resources. I’m hoping that some of you might share your feedback / expertise as I progress…

For the unvented, ~1/12 shed roof this is my plan:

Roof from inside to outside:

LVL rafters R24 batts tight to underside of roof sheathing

ZIP roof sheathing, taped

~R26 over roof sheathing: 3″ Polyiso with 2″ Toprock DD on top of Polyiso EPDM roofing, .060, over Toprock Total roof assembly

~R50

Walls from inside to outside:

2×6 batt insulation (likely R23 Rockwool)

ZIP sheathing, taped

1.5″ Polyiso, taped, over sheathing

3/4″ Rainscreen cavity

siding

I plan to run the sheathing and exterior wall insulation up to the roof sheathing, over the rafter ends. The roof sheathing is planned to extend into the built-up roof overhang as shown in the detail. This is a hybrid plan from some of the details in the detail library on this site. This is a preliminary detail with many components not shown. Any glaring issues or things that I should reconsider? Thanks in advance.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Under most codes, since roofs with continuous exterior insulation have much better thermal performance, can pass based on assembly U factor. In most areas this works out to an R38 assembly. Going up to R50 with expensive insulation such as polyiso or mineral wool has ROI measured in centuries both in terms of energy use and embodied CO2. I would run your assemblies through one of the one-line calculators such as this to see what would work:

https://www.ekotrope.com/r-value-calculator

Even taking into account cold weather R value de-rating, mineral wool over polyiso here buys you nothing just extra cost and height. A cover board over the polyiso is a good idea as it will make re-roofing much easier.

I'm not sure how you are planning to add slope, but the simplest is typically tapered polyiso. Sloping the structure or adding tapered sleepers is possible but more work than the tapared foam.

Make sure to figure out all your air barrier transition details, usually the weak spot on this type of add on is tying into the existing house. Besides being a big potential air leak, these are usually the weak spots where you get water leaks. You might need more height under your windows just to deal with this properly. You can run your rafters in the 12' direction to reduce span thus size to save a bit of height as well.

It sound like the extension won't be the full width of the house, I usually find adding extending the roof to cover part of the patio to be useful. A roof over a deck makes the space much more useful both in the sun or when it rains.

Steve,

Akos had given you good advice. The only thing I'd add was you might want to consider furring under under the drip-flashing so any water drops directly off the roof, rather than running down the fascia.

Akos and Malcolm,

Thanks for the feedback, great info. I'll spend some more time looking at the calculator and exploring other insulation options. The tapered Polyiso sounds like an interesting option. I had originally headed in the direction of the Toprock over the Polyiso for 2 reasons: The Toprock is very dimensionally stable for and EPDM substrate and also would insulate the Polyiso so that it's R-value would be less susceptible to cold weather de-rating. But I need to re-look at this.

I fully agree that the existing house / addition transitions will be critical. I'll be putting together a plan for those areas soon. I'm sure I'll have questions.

I like the idea of extending the roof over the patio. I'll need to consider this as well. We have an amazing Magnolia tree the extends over the patio so that may pose a challenge.

马尔科姆-同意,关于滴闪烁。这still needs to be detailed. I like the looks of PERMAROOF UPVC 2 PART GUTTER TRIM for EPDM roofs, which is a UK product...not sure if I'll be able to find it in the U.S. Anyone here have experience with this product? or a source state-side?

Thanks!