Image Credit: David White

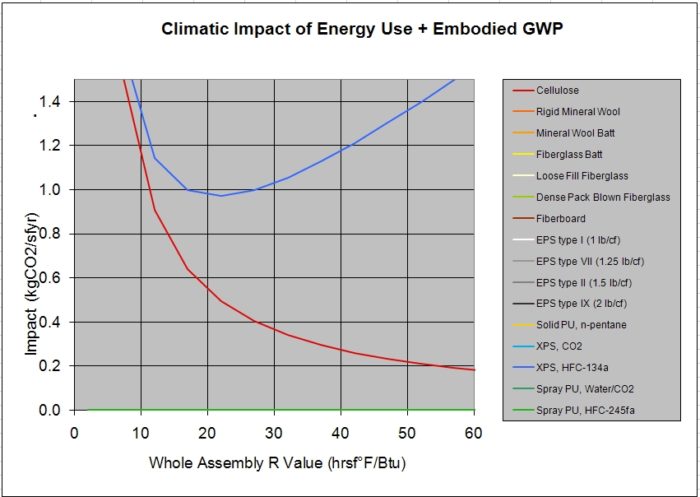

In June 2010, Alex Wilson published a ground-breaking article,“Avoiding the Global Warming Impact of Insulation,”inEnvironmental Building News. In the article, Wilson examined the implications of the fact that the HFC blowing agents used to make extruded polystyrene (XPS) and most types of closed-cell spray polyurethane foam have a much greater global warming impact than CO2. As it turns out, the negative global warming impacts of escaped blowing agents from some types of foam insulation can sometimes outweigh the positive climate impacts attributable to energy savings.

Needless to say, the article generated a great deal of discussion. (A shorter version of Wilson’s article appearedas a blog on GBA.) As a direct result of this article, XPS became the pariah of the rigid-foam world — at least for green builders. (The problem of HFC blowing agents should not be confused withquestions surrounding the flame retardant HBCD, another problematic component of some types of foam insulation. Because both XPS and EPS contain HBCD, the “greenest” type of rigid foam is polyisocyanurate.)

How insulation materials influence climate change

Insulation materials can affect our climate in at least three ways: one positive way and two negative ways.

Weekly Newsletter

建筑科学和能源效率的建议,plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member?Log in

13 Comments

Greener Foam

Martin,

I thought there was talk a while back of a greener blowing agent for XPS made in the US (Dow).

Response to Doug McEvers

Doug,

I think you are confusing the problem of ozone depletion with the problem of a chemical's global warming potential.

Foam manufacturers have made great strides in the last 30 years at reducing the ozone depleting potential of their blowing agents. You may have read Dow's press release on this issue:

http://building.dow.com/media/news/2007/20071205a.htm

However, just because a blowing agent doesn't deplete the ozone layer, doesn't mean that the blowing agent doesn't have a high global warming potential. Here's what Alex Wilson had to say on the issue in his article:

"Two common foam insulation materials are produced with hydrofluorocarbon (HFC) blowing agents that are potent greenhouse gases— extruded polystyrene (XPS) such as Dow Styrofoam of Owens Corning Foamular, and standard closed-cell spray polyurethane foam (SPF). ... Manufacturers are working to develop and deploy fourth-generation blowing agents that have zero or very low GWP while still providing the various performance and safety properties that are required. Such developments would alter the conclusions of this article. Both Dupont and Honeywell are working on hydrofluoroalefin (HFO) blowing agents. At the 2010 NESEA Building Energy Conference, Gary Loh of DuPont described a zero-ODP, low-GWP (less than 10), nonflammable, low-conductivity blowing agent, for SPF, FEA-1100, that is currently undergoing toxicity testing and should be introduced (if toxicity testing continues to demonstrate safety) sometime between 2013 and 2015. Honeywell already has a similar product on the market in Europe for one-component polyurethane foams (HFO-1234ze) and expects to broaden its family of HFO blowing agents. When these new products replace the HFC-blown insulations in the coming years, the argument for avoiding SPF and XPS on the basis of lifetime GWP should largely disappear."

In Europe, manufacturers of XPS have already switched to blowing agents with a low global warming potential. But these blowing agents result in XPS with an R-value of R-4 per inch. If your Dow Styrofoam has a label that says R-5 for 1 inch or R-10 for 2 inches, it's a safe bet that you've got the type of "bad" Styrofoam with a damaging blowing agent and a high global warming potential.

Recycled Rigid Foam Panels

I have been able, through vigorous searching, to always find once used rigid foam insulation panels. Besides the significantly lower cost, my take on the above issue is that the greatest majority of HFC release occurred with the manufacture and is part of the 'inherent global warming value" of the original structure where it was used. What I am doing is the "highest and best use" of the C&D waste when the original structure was re-done. I am getting the benefit of the insulation value with only some attached transportation 'deficit', and saving land fill space for some other poorly conceived disposal option. That sounds too smarmy - I think re-use of the original item with no additional manufacturing requirement should be a goal. The lower upfront cost is an added benefit. Am I missing something in my appraisal?

Reply to Rock Termini

Rock,

Your question is similar to the one posed by someone who opposes the use of animal fur to make clothing, but who nevertheless buys a mink coat at the local Goodwill store because after all, "the animal is already dead."

Your question is one for philosophers and moralists rather than engineers; there is no simple answer. Personally, I admire your decision to re-use building materials that might otherwise end up in a landfill.

Reuse and diversion

Rock,

I agree with your philosophy. There are many benefits to reusing and diverting. You save money by not purchasing a new product. The rigid foam was created and used by another builder. The original manufacturing process has already contributed to the global warming effect. By diverting and reusing the rigid foam, you reduce the need to manufacture and transport another new product. There is less waste transported to the landfill and buried. The insulation reduces your consumption of fossil fuel for heating and cooling. Seems like a winning proposition. Jim

composite assemblies

If I understand the the excel tool properly, it compares global warming potential between given assemblies where each assembly is entirely constructed of a single material. In a typical application I might specify 2" XPS outside of a wood stud wall. Assuming R10 for XPS and R8 for EPS, 6000hdd, and "high" agent release, the graph shows 1.35kgsCO2/sfyr (extruded) vs 1.4kgsCO2/sfyr (expanded). Advantage XPS because of it's superior insulating properties. This advantage is increased if the release is assumed "low". Am I misunderstanding the tool?

Also, I am interested in data on the off-gassing of the blowing agents. Not that I trust the manufacturers information, but NCFI Polyurethane claims that in it's closed cell spray foam there is no off gassing of HFC245a "at any appreciable level under ordinary conditions".

composite assemblies

I see now that the excel tool allows input for insulation in addition to the foam in question. For a 2x6 or 2x8 frame wall with cellulose, the curve begins to rise immediately for XPS and continues to dip for EPS.

Impacts of Open Cell Foam (w/ Water Based Injection).

This is some great information and that chart does a great job shedding some light on the GWP vs R-Value relationship. If this chart were to include the air sealing properties of the various insulations, I imagine the GWP of water based injection spray foams would be very low.

I understand that insulating with plastic has it's drawbacks, but it's inherant air sealing properties provide some serious benefits as well. Clearly, avoiding using XPS and HFC injection SPF makes sense from both a global warming and ozone depletion stand-point. But given that open cell foam uses 1/4 as much plastic as closed cell and is widely available in water based injection methods, what are some of your thoughts on the overall impacts of using open cell foam for insulating? Are there any studys that you can bring to my attention?

Thanks

Response to Tyler Dotten

Tyler,

Q. "What are some of your thoughts on the overall impacts of using open cell foam for insulating? Are there any studies that you can bring to my attention?"

A. The Excel spreadsheet described in this blog addresses your question, at least in terms of global warming potential. The use of open-cell spray foam does not contribute to global warming, even when installed to a high R-value. The same cannot be said of closed-cell spray foam.

Re: Response to Tyler Dotten

Martin,

Thanks for responding to my post. That spreadsheet simply said Spray P/U Water/CO2. I wasn't sure if this was refering to open cell foam or closed cell. The R-Value per inch that I usually see associated with Open Cell is 3.8. The excell spreadsheet assigns an R-value per inch of 5 with the

said PU. For that reason I assumed it wasn't open cell (or low density) foam. From what I understand the amount of plastic used for an open cell foam is about 1/4 the amount used for a closed cell product, so they would obviously score quite differently on this GWP calculation.

Additionally, this spreadhseet and article are exceptionally helpful when it comes to comparing Rvalue to GWP, but it deliberately takes air sealing out of the equation. One of the main benefits of spray foam lies in it's air selaing qualities.

There are seemingly endless ways to look at the +/- of different insulation products (environmental impacts of production, fire saftey, off-gassing, r-value air sealing etc.), all insulation products will score high in some of these areas, but fall down in others. As much as I understand there is no way to quantify all of these impacts, I am trying to figure out if open cell spray foam is a "best-practice" type of product. As a homeperformance company, we do a lot of insulating and our current policy is to avoid foam insulations. For obvious reasons I embrace this policy as it applies to most closed cell spray foams and XPS rigid. My question is, do all of the negative impacts of open cell foam w/ water blown projection, outweigh the great air-sealing/r value benfits the product provides? If there are any further studies or educated people who can weigh in on this, it would sure help us (and a lot of other people) out.

Thanks for your time,

Tyler

Another response to Tyler

Tyler,

I agree that David White's default value for open-cell spray foam (R-5 per inch) is too high. I have sent David an e-mail asking him to clarify that value on his spreadsheet. Thanks for pointing it out.

而大卫的电子表格是有用的,他从不claimed that all of the environmental virtues and drawbacks of an insulation product could be caught in a single formula. All the spreadsheet does is help clarify the GWP of released blowing agents, comparing that effect to CO2 reductions due to the insulating value of the products under consideration.

The analysis does not address air leakage.

Here's the thing: it's possible to build a very tight house without any spray foam, so it's hard to know whether to credit spray foam with improvements in airtightness. Even if one wanted to, the thermal reductions attributable to that particular quality of the spray foam would be very hard to quantify.

So, here's the bottom line: there is no mathematical formula to weigh these effects. It all boils down to judgment.

More info from David White

Tyler,

David White just e-mailed me. His spreadsheet does NOT include open-cell spray foam in his listed insulation options. The reason for the omission, according to David, is that he "had no data on embodied GWP" for open-cell foam.

The option titled "Spray P/U Water/CO2" is actually a brand of closed-cell spray foam that happens to be rated at R-5 per inch.

I was curious about something like the effect size of this concept of Global Warming Potential, so I did some math. It's weird to talk about GWP without any estimate of effect size. What I wanted to know was whether the GWP of insulation materials actually matters -- whether it adds significantly to greenhouse effects.

So I took a higher value from the graph: 1.2 kgCO2/sfyr, which corresponds with an R-40 assembly. I have no idea how many square feet of insulation is realistic, so I took a high guesstimate of 2,000 sq ft, based on typical floor area, which must be significantly greater than typical exterior wall area.

Thus, 1.2 × 2,000 = 2,400 kgCO2/yr for one example house.

Then I multiplied this figure by 100 million assuming that 100 million households installed this amount of XPS insulation in one year (a deliberately wild overestimate, even if we combined North America and Europe, I suspect).

100 million × 2,400 = 240 billion kgCO2/yr

We release about 36 gigatons of CO2 into the atmosphere per year. That's 36 billion tons, or 36 trillion kilograms. So I divided 240 billion into 36 trillion, which comes to 0.0067, or 0.67 percent.

So the aggregate contribution of 100 million homes decked out with R-40 levels of XPS foam in all of their exterior wall area (and maybe some attic area too given my conservative 2,000 sf overestimate) is 0.67% of overall CO2 emissions (or CO2 equivalent, if this is about other gases, blowing agents, etc).

That's more than I expected. It's still pretty small. I'm not sure whether we should care about it or not. This is mostly about heating and cooling, and I'm not clear on how much of a delta it is from the average home using fiberglass batts or whatever – I assume it's a net CO2 reduction compared to the average home...

Log in or become a member to post a comment.

Sign up Log in