Vented / unvented roof assembly

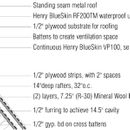

We are designing a relatively high-performing building envelope and coming up against challenges with the roof assembly. The roof will be a cathedral ceiling (finished interior surface). The challenge is due in part to the steepness (15:12) of the roof. Typically, we would do some combination of exterior rigid and cavity batt insulation, but the steepest tested screw pattern that we can find for the exterior rigid is 12:12. So, I am wondering if we can make a pseudo-vented roof assembly, as per the attached detail. All components of the assembly are vapor permeable. For air-sealing purposes, we would wrap the entire structure with a continuous layer of vapor permeable air barrier (Henry Blueskin). On the roof, we would then create a ventilation space – outboard of the air barrier. Then over battens there would be a continuous plywood layer and a waterproof ice-and-water membrane beneath a standing seam metal roof.

Thoughts? Comments?

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Per code, you cannot install permeable insulation against the roof decking or ventilated channel. I would recommend to spray 2" ccSF R13 min. (or more depending on your location) against the roof decking and then install the mineral wool insulation.

P.S. Correction on permeable insulation.

Thanks for the comment, Armando. I think you meant to say that one CANNOT install PERMEABLE insulation against the roof deck per code. Going the spray-foam route would be IMPERMEABLE. In climate zone 5, I'd be looking at 3-4 inches of foam minimum. Beyond the inherent costs associated with that, I have concerns about the long-term efficacy of spray foam. We've certainly used it to achieve 'code-compliant' assemblies, but I am concerned that over time it might not be the panacea it claims to be. I'd be curious if you could provide a citation for the 'against the ventilated channel' comment. The detail I am positing is only different from a ventilated roof assembly in that there is an air barrier outboard of the insulation. There is still an air space to provide a cold roof and mitigate ice damming (frankly a non-issue given the steepness of the roof and the fact that snow will immediately shed). The airspace would also wick any vapor drive from the interior. Any water vapor that made it through the vapor permeable mineral wool would also pass through the vapor permeable membrane. The same with any condensation or moisture sorption given that the dew point will periodically fall in the insulation.

While I do not fully ascribe to the No-Foam Camp, I do have an affinity for more 'ecologically-minded' options. Additionally, I believe that completely impermeable materials/components/assemblies should be approached with caution (e.g. Spray Foam). Set against the millennia in which mankind has been making buildings, we've only started trying to seal them up in the past few decades.

Thanks for the correction above, I meant permeable. You are correct that in CZ5 you are required to install 3" R20 min. of ccSF, but the code (2015 IRC 806.5.1.) is very specific on that... either go above or below the STRUCTURAL sheathing, not a vented channel.

When you say 14" rafters, are they TJIs? If so, you could install rigid foam boards against the decking, or maybe you could install the rigid foam below the top cord of the TJIs to create a vented channel, but I've not specified that installation before.

I really don't understand the "1/2" plywood strips, with 2" spaces"... can you explain further?

My concern with ccSF or any material intended to be impermeable is that 1. there may be gaps upon install or 2. the material may shrink over time creating gaps. Then the Achilles heel is exposed.

So rather than go the impermeable route, I'm wondering if I can do a permeable - vented roof, but have the air-barrier outboard of the insulation. I know Lstiburek and others have wonderful details for air-sealing at the gyp, but I think this is unrealistic in practice and/or prone to failure since it requires meticulous attention to detail by several trades.

I'm attaching here an alt. version of the detail. I changed the "plywood with spaces" to spaced furring strips (Sim. to the decking for a cedar shingle roof).

What I'm proposing may be impractical/inappropriate. And that's why I'm throwing it to this forum as well as to some colleagues before taking it any further. I sincerely appreciate your input.

Kopec Arch.,

First of all, I don't think the difference in screw performance for a 15/12 roof (compared to a 12/12 roof) will be significant enough to scuttle your rigid foam plans. You might want to talk to your local building inspector to see if this issue is real or imagined.

Second, I think that your first attempt at an assembly could (with modifications) work, and I think that Armando Cobo's objections might not be shared by all building inspectors. You might get a variation of this approved. What you are looking for is a vapor-permeable roof sheathing. I don't think that strips of 1/2 inch plywood, with gaps, is what you want. I would suggest old-fashioned board sheathing -- although you could also use fiberboard sheathing. Either of those would be vapor-permeable, and would allow for easier installation of the Henry Blueskin VP100.