How to Protect the Bottom of Exterior Siding Insulation / Rainscreen

I have 5″ of exterior Rockwool insulation on my new build and am wondering what options I have for protecting the bottom of it? Do I NEED to protect the bottom of it?

是的,我有en the perforated metal that is often used. I priced this out and it is $8 per lineal foot in my area which equates to $1500 for the flat stock raw material. That seems really excessive to me given that I have another flashing piece right below it to go over our foundation. I’ve attached a picture of my foundation plan.

I need to determine if I need to protect that Rockwool and what options I have that might not be so expensive.

Then, I am also wondering if I have alternatives to Coravent that are an option for my rainscreen or if that is really the only option for protecting the bottom of the rainscreen.

Thank you!

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Treated plywood is a cheap option (maybe not right now though). It would protect the insulation from getting dirty and from physical damages. Don't think it's a necessity but a nice insurance.

You can't leave any gaps for critters to get into, animals love to make nests in insulation. I've used bent pieces of perforated soffit panels before for this. Perforated leaf guards might also be about the right size.

Stainless hardware cloth could also work.

Hi Michael,

ThisQ&A threadaddresses your question at some length.

Michael,

Where is your WRB located? If it is outside the Rockwool you can assume that bulk water will not drain out the bottom of the insulation and can build a 2"x wood ledge instead of the perforated flashing usually used. That will also give you a nailing base for either the Cor-a-Vent or perforated J flashing at the bottom of your rain-screen strapping.

If your WRB is outside the Rockwool there is also no reason for the cap-flashing above your field stone base.

我用Prosoco液体闪光产品和哈ve liquid-applied WRB on the CDX plywood. So, my WRB is at the sheathing layer.

Given that, what would you recommend? It seems that I've exhausted my options on the perforated aluminum, unless I find something else through a different supplier, it just seems too costly.

Michael,

I'd probably go with Ako's suggestion and use stainless hardware cloth covering a bug screen.

Any chance of moving the framed walls in so that only the rain-screen strapping overhangs?

Hi Malcolm,

I am afraid not... The entire house is framed, trusses and roof deck on, etc. We're air-sealing and waterproofing the sheathing right now and then would move to the Rockwool.

We have window bucks that protrude from the wall that are liquid-flashed.

I suppose I could add a secondary WRB outboard of the Rockwool, but it seems that might be difficult to execute (what to attach it to).

Michael,

Looks like it's going to be a nice place!

I agree - I can think of lots of things I'd rather spend 2K on than perforated flashing. The hardware cloth and bug-screen are a pretty good solution. Most of the damage to bug-screen at the bottom of cavities comes from weeds or grass growing through them. A bit of diligence and that shouldn't be a problem.

Thanks Malcolm!

To be clear, I need to use stainless, I get that. But do I need both hardware cloth and bug screen?

And if so, they both should be stainless?

I have one more lead a couple hours away that may have perf flashing. If that doesn’t work out I’d go with this alternate.

Michael,

You are trying to keep out two things: rodents and insects. That's the advantage of the perforated flashing which can do both. The big problems with just using something fairly fragile like bug-screen, or omitting the hardware cloth, is how difficult it would be to retrofit later.

Hi Malcolm,

Are there concerns about rodents being able to chew through stainless mesh like this:

https://www.metroscreenworks.com/rolls-of-screen-all-types/stainless-steel-security-screen/

Michael,

I used a copper bug screen that I got from metroscreenworks.com. It comes in various length rolls that you can cut to the size you need. I unfortunately did this after the 3" of ComfortBoard and all the trim was up because I did not have a solution at the time. So in my case I had to cut the copper into 3' long sections that were 8" tall and then use a scraper to friction fit the pieces in. It works quite well, but if it would have been much easier if I did before the ComfortBoard was attached. In that case, I could have used long strips of the copper, taped it to the Zip, then attach the ComfortBoard, wrap the copper up and secure it to the furring strips and then place a bead of caulk on the copper right before attached the skirt board. I will post a picture of what it looks like later today.

Thanks for the feedback Jonathan!

Can you tell me what the bead of caulk on the copper before attaching the skirt board is for? Is that just so that in between the furring it isn't loose allowing critters to slip in?

Also, why copper instead of stainless?

Thanks.

Copper, bronze or stainless bug screen would all work. All are corrosion resistant and would last nearly forever in that location. Bronze might not be quite as corrosion resistant in a salt environment, depending on the bronze alloy. If those are not easily available, vinyl bug screen is very cheap, but somewhat fragile, so layering it with stainless hardware cloth would be a good idea. The stainless would deter critters chewing, and the bug screen would stop the insects. I would still consider using the Coravent between strapping so that the screening doesn't wrinkle and gap behind the siding or trim board.

Michael,

Copper is good for the reason Peter mentioned, plus it is a deterrent for ants and termites. You are correct on my reason for the caulk. I have a Coravent above the skirt board where the the drip cap is, and that does a good job of keeping things tight enough to keep out mice, but in some spots there is enough room between the skirt and the ComfortBoard for things as big as bees to get in there and that is what I am relying on the copper keep out.

At the risk of sounding dense... Can't I just wrap the bottom of the 5" of mineral wool with typical aluminum flashing?

I could simply drill a bunch of drain holes in case water were to get behind the cladding and the rainscreen layer. That would be easy to source and last forever.

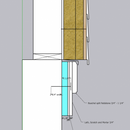

Is this asking for water issues? See screenshot.

I could even screw the flashing into the wall on top of a layer of something like Mortairvent or a vented mesh to allow drainage behind it.

It seems unlikely that water would even get back behind the 5" of Rockwool and rainscreen strapping, but if it does wouldn't this still be okay?

Seems more durable than just the mesh.

If everyone still thinks just stainless bug screen is best, I'll go that route.

如果我正确阅读彼得的评论,I don't need hardware cloth AND mesh if I use a stainless bug screen, is that right? Bugs can't get through and rodents won't be chewing through stainless...

Thank you!

On all my DERs with exterior foam up to 8", I have the foam (in your case mineral wool) sit on a slightly sloped galvanized pan nailed to the sheathing. Then the S/S bug screen (from most big box stores) is tacked above that onto the sheathing. It's left hanging down during the exterior insulation hanging process. Then pulled up 18" and tacked to the furring strips. Very tight when the siding goes on and I've never heard of problems with this in 12 years of doing it.

PK

Hi Paul,

I am curious if when you do that if you still use something like Coravent or is the stainless steel screen all of the protection for the ventilation channel?

That's it Michael. Haven't used anything but in 5 rebuilds.

Hey all, figured I'd just post a quick update. This ended up being pretty easy to find once I started Googling "perforating" companies. I found Clark Perforating in Michigan, called them up and they produced 12" wide coil stock with perforations and delivered it to me in Wisconsin within a couple weeks.

Great resource if anyone ever needs to find this material. Price was pretty reasonable too. Roughly $3/foot

Michael,

Good to know. Having that at the base just solves all the potential problems.

Michael, I am curious, what material is that coil stock?

It’s .032 aluminum

Hi Michael,

Did you use the same perforated metal for where the rainscreen meets at the top and bottom of the window?

Thank you,

Arnold

Arnold,

My own feeling is that the risk of bulk water infiltration around the window outweighs the advantage of slightly better venting of the rain-screen there. Below the window leave your furring down enough to allow horizontal air-movement around the frame, and above keep your cladding up over the head-flashing 3/32" or so to allow water to escape.

Hi Malcolm,

Unless I am misunderstanding you, what are you using to keep the insects out from entering the rainscreen around the window?

Thanks,

Arnold

Arnold, what Malcolm suggests here is what we did.

What hole size did you end up using for the perforated material?

I was thinking of using 0.063" but there a 15 week lead time and it's also twice the cost compare to the 0.125". I am just concern the 0.125" may be large enough to allow some insect like ants to get through.

Thank you,

Arnold

We did .032 3003-H14 Aluminum

1/8 perfs on 7/32 staggered centers

You can add fiberglass bug screen inside pretty easily. I unfortunately did not but I meant to. I showed up on site one day and the crew had not incorporated this detail. Hoping I don't have a problem with bugs at 1/8".

Michael,

My experience has been that insects which can get through 1/8" perforated stock (sugar ants, ladybugs, etc.) are small enough to get in other ways.

We decided to go with the 0.125 (1/8") perforated hole and lay some aluminum insect mesh on the inside. For around the windows and at the top of the rainscreen, we'll just use the insect mesh but double it for extra strength is rigidity.

Arnold