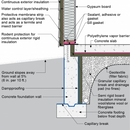

No fines in base for conc slab on grade

I just perused the recommendations for Building Science Corp Insight #118 for insulating concrete slabs on grade and noticed the gravel base is always labeled with “no fines”. Having recently tried to educate myself on the various types of gravel bases for permeable paving, I had found a 2012 position paper by the American Society of Concrete Contractors, ASCC Position Statement #37, that states open-graded bases (no fines) don’t meet ACI requirements for base material because they are relatively incompactible, difficult to trim, and unstable. Based on their recommendations, it seems the better choice is to add a min 10 mil vapor barrier over the gravel and terminate at the stem wall.

I’d be interested to hear anyone’s experience with no fines base under slabs on grade.

Thanks,

Dan Allen

https://www.buildingscience.com/documents/building-science-insights/bsi-118-concrete-solutions

https://ascconline.org/Portals/0/docs/Secure%20Position%20Statements/PS-37_Open-Graded%20Base_Web_SC.pdf

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Daniel,

The two concerns of the ASCC don't apply to slabs with rigid insulation and vapour-barriers between them and the base. The wet concrete can not penetrate the base, and construction traffic can not affect the grading. Their advice makes a lot of sense for driveways, patios, carports, etc.

Malcom,

Thanks for the response. Have you had success with open graded bases? I agree that the separation of the insulation and/or vapor barrier addresses the ASCC concern about mortar entering the base, but their position is still that the open graded bases are less stable. And they say that because the reduction of water inflow due to gravel is minor compared to the vapor barrier, it isn't worth the risk. My concern is that if I specify open graded base but the contractor objects, they can point to an industry recommendation and try to avoid responsibility for slab problems.

"ASCC contractors believe that a dense-graded base covered by a 10 mil vapor retarder (as recommended in ACI 302.1R-04) is the best arrangement for interior slabs. For exterior slabs, the ACPA recommends neither an open-graded base nor use of a vapor retarder.

ASCC contractors will place slabs on an open-graded base course if required by specification, but only with the acknowledgment that the risk of cracked or thin slabs is entirely the responsibility of the specifier."

Daniel,

Yes we routinely use a layer of clear-crushed below the slab as a capillary break. It only needs to be 4 to 6" deep, so the concerns around stability don't arise, nor do problems with grading, so no "thin slabs". You can't compact it, but it still benefits from being consolidated, so we do use a plate compactor when levelling.

Concrete is something that always has different players wanting different specifications based on their interests. Finishers want a wetter mix to get a smoother surface. Engineers want you to pour so dry you have trouble avoiding honey-combing. The ASCC is understandably only interested in what they consider the best substrate for their members to use, but their interest doesn't extend to the best practices of sub-slab water management.

I'm getting a bit sick of industry groups and manufacturers basically saying if you don't do it exactly as we want we withdraw our warranties. It smacks of just wanting to think up as many excuses as they can to avoid responsibility for their work.

"but their position is still that the open graded bases are less stable"

I don't have a horse in this race, and little experience prepping slabs, but from reading the ASCC doc, I think the 'stability' they refer to is in reference to stability against construction traffic, which causes the rutting (etc.) and in turn, uneven slabs. In other words, if rigid insulation has been laid with some care, this should make that point moot as well. Instability in this case doesn't mean open-graded aggregates collapse on themselves. It's displacement.

Their arguments in favor of a compactable fill seem to become largely moot when there is rigid foam. On the other hand, perhaps they're correct that having the capillary break of a no-fines fill is not as critical in an on-grade scenario, so long as a VB is used and the exterior perimeter is well drained. 6 in one...?

Note the the BSC drawing includes a drain, which won't work well without clean gravel. Similar for any radon mitigation.